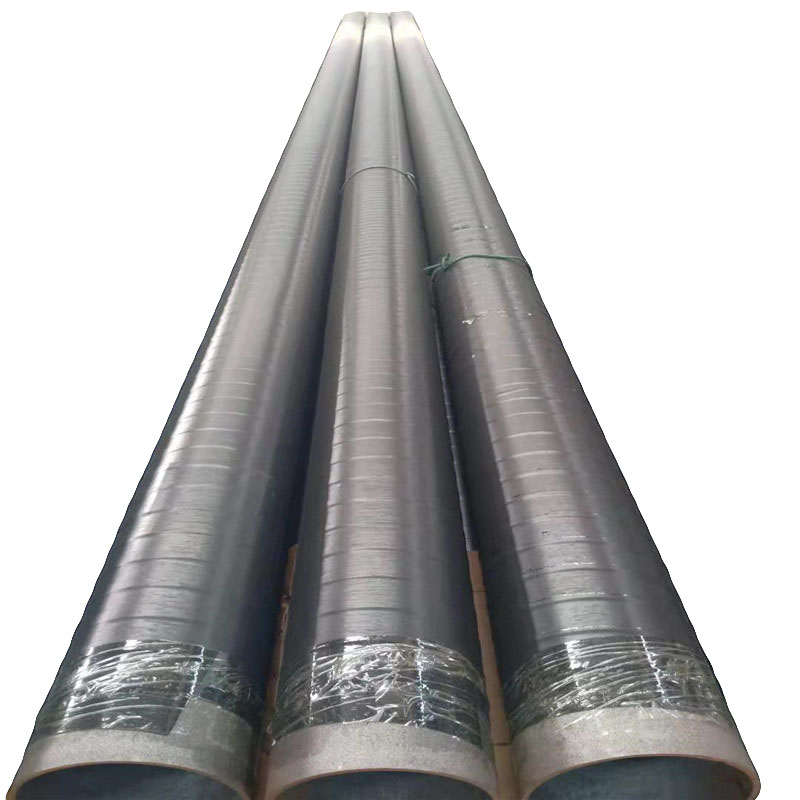

Pipe ea tšepe ea boleng bo phahameng ea Spiral

Pipe ea tšepe ea boleng bo phahameng ea Spiral

Lisebelisoa tsa liphaephe tsa spiral tse sebelisoang ka tloaelo Chaena ka kakaretso li kenyelletsa: Q235A, Q235B, Q345, L245, L290, X42, X52, X60, X70, X80, 0Cr13, 1Cr17, 00cr19ni11, 1Cr18Nicr1b9 le 01b9Litekanyetso tse tloaelehileng tsa liphaephe tsa spiral ka kakaretso li arotsoe ka: SY / t5037-2018 (tekanyetso ea bosebeletsi, eo hape e tsejoang e le spiral seam submerged arc welded steel pipe bakeng sa phala e tloaelehileng ea phetiso ea mokelikeli), GB / T9711.1-1997 (tekanyetso ea naha, eo hape e tsejoang e le Maemo a phetisetso ea tekheniki ea phepelo ea tšepe bakeng sa indasteri ea oli le khase, karolo ea I: sehlopha sa phala ea tšepe (GB / t9711.2 phala ea tšepe ea sehlopha sa B e nang le litlhoko tse thata)), api-5l (American Petroleum Association, eo hape e tsejoang e le pipeline steel pipe). );Ho kenyeletsoa PSL1 le PSL2), SY / t5040-92 (spiral submerged arc welded steel pipe for qubu).

(1) lisebelisoa tse tala, ke hore, hlobolisa tšepe coil, terata tjheseletsa le flux.Tlhahlobo e tiileng ea 'mele le ea lik'hemik'hale e tla etsoa pele ho kenyelletsoa

(2) Lenonyeletso la hlooho ea tšepe le mohatla le nka terata e le 'ngoe kapa terata e habeli e ka tlas'a metsi,' me welding e kenelletseng ka tlas'a metsi e amoheloa bakeng sa ho lokisa tjheseletsa ka mor'a hore e kene ka har'a phala ea tšepe.

(3) Pele ho etsoa, tšepe ea strip e ea lekanngoa, ea fokotsoa, ea raloa, ea hloekisoa holim'a metsi, ea tsamaisoa le ho kobeha pele.

(4) Tekanyo ea khatello ea khatello ea motlakase e sebelisoa ho laola khatello ea moqomo oa oli o hatellang mahlakoreng ka bobeli a sepalangoang ho netefatsa lipalangoang tse boreleli tsa tšepe ea strip.

(5) Amohela taolo ea kantle kapa ho theha lethathamo la taolo ea kahare

(6) Sesebelisoa sa ho laola lekhalo la weld se sebelisoa ho etsa bonnete ba hore lekhalo la weld le finyella litlhoko tsa ho tjheseletsa, 'me bophara ba phala, ho se lumellane le lekhalo la weld li laoloa ka thata.

7

(8) Li-wellds tsohle tse cheselitsoeng li hlahlojoa ke mochine o tsoelang pele oa ultrasonic othomathike oa phoso ho netefatsa hore 100% NDT e fana ka tšireletso ea spiral welds.Haeba ho na le bofokoli, e tla lla le ho fafatsa matšoao ka bo eona, 'me basebetsi ba tlhahiso ba tla fetola mekhahlelo ea ts'ebetso ka nako efe kapa efe ho felisa liphoso ka nako.

(9) Pipe ea tšepe e khaola likotoana tse le 'ngoe ka mochine oa ho itšeha ka plasma ea moea

(10) Ka mor'a ho khaola ka phala e le 'ngoe ea tšepe, sehlopha se seng le se seng sa phala ea tšepe se tla ba tlas'a tsamaiso e tiileng ea pele ea tlhahlobo ho hlahloba thepa ea mochine, sebopeho sa lik'hemik'hale, boemo ba ho kopanya, boleng ba holim'a phala ea tšepe le NDT ho netefatsa hore phala e etsoa. ts'ebetso e tšoaneleha pele e ka kenngoa ka molao tlhahisong

(11) Likarolo tse nang le matšoao a tsoelang pele a ho lemoha liphoso tsa acoustic holim'a weld li tla hlahlojoa hape ka manual ultrasonic le X-ray.Haeba ho na le bofokoli, ka mor'a ho lokisoa, ba tla boela ba be tlas'a NDT ho fihlela ho netefatsoa hore liphoso li felisitsoe.

(12) Phaephe ea seam e tjheseletsang butt ea strip steel le T-joint intersecting spiral weld e tla hlahlojoa ka X-ray television kapa filimi.

(13) Pipe e 'ngoe le e' ngoe ea tšepe e tlas'a teko ea hydrostatic, 'me khatello e amohela tiiso ea radial.Khatello ea teko le nako li laoloa ka thata ke mochine oa ho lemoha microcomputer oa khatello ea metsi a phala ea tšepe.Litekanyetso tsa liteko li hatisoa le ho rekotoa ka bo eona

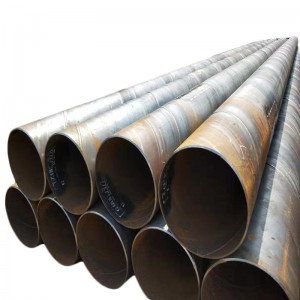

(14) Qetello ea phala e entsoe ka mokhoa o nepahetseng ho laola perpendicularity, angle ea letsoapo le bohale bo sa hlakang ba sefahleho sa ho qetela.Spiral seam submerged arc welded pipe bakeng sa lipalangoang tsa mokelikeli oa khatello e sebelisoa haholo bakeng sa liphaephe tse tsamaisang oli le khase ea tlhaho.

Pipe ea tšepe e na le matla a matla a ho jara khatello le polasetiki e ntle, e loketseng ho cheselletsa le ho sebetsa;Spiral seam submerged arc welded steel pipe bakeng sa phetiso ea mokelikeli o tlase oa khatello e tlase e entsoe ka mahlakore a mabeli a othomathiki a ka tlas'a metsi kapa mokhoa oa ho tjheseletsa o nang le lehlakore le le leng, o sebelisetsoang phetisetso ea mokelikeli o tlase joalo ka metsi, khase, moea le mouoane. .

Peipi e otlolohileng ea seam welded e na le melemo ea ts'ebetso e bonolo ea tlhahiso, ts'ebetso e phahameng ea tlhahiso, litšenyehelo tse tlase le nts'etsopele e potlakileng.Matla a pipi e cheselitsoeng ka spiral hangata a phahame ho feta a phala e otlolohileng e cheselitsoeng.E ka hlahisa phala e cheselitsoeng e nang le bophara bo boholo ba phala e nang le sekheo se moqotetsane, 'me phala e cheselitsoeng e nang le bophara bo fapaneng ba phala e nang le bophara ba bophara bo tšoanang.Leha ho le joalo, ha ho bapisoa le pipe e otlolohileng ea seam e nang le bolelele bo lekanang, bolelele ba weld bo eketseha ka 30 ~ 100%, 'me lebelo la tlhahiso le tlaase.Ka hona, tjheseletsa ea seam e otlolohileng e sebelisoa haholo bakeng sa liphaephe tse cheselitsoeng ka bophara bo nyane, 'me welding ea spiral e sebelisoa haholo bakeng sa liphaephe tse cheselitsoeng ka bophara bo boholo.Pipe ea Spiral e sebelisoa haholo ho boenjiniere ba metsi a pompo, indasteri ea petrochemical, indasteri ea lik'hemik'hale, indasteri ea matla a motlakase, nosetso ea temo le kaho ea litoropo.Ke e 'ngoe ea lihlahisoa tsa bohlokoa tse 20 tse ntlafalitsoeng China.Bakeng sa lipalangoang tsa metsi: phepelo ea metsi, drainage, boenjiniere ba ho hloekisa likhoerekhoere, lipalangoang tsa seretse, lipalangoang tsa metsi a leoatle.Bakeng sa phetiso ea khase: khase, mouoane le khase ea peterole e nang le mokelikeli.Bakeng sa sebopeho: joalo ka phala ea ho khanna qubu le borokho;Liphaephe tsa boema-kepe, meaho ea litsela le meaho, lipeipi tse bokellang marine, jj.