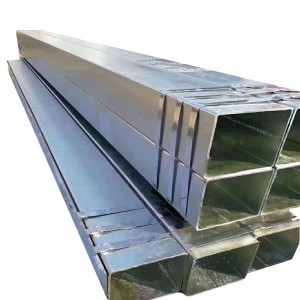

Pipe ea tšepe ea boleng bo holimo

Pipe ea tšepe ea boleng bo holimo

Brinell, Rockwell le Vickers hardness indexes hangata li sebelisoa ho lekanya ho thatafala ha lipeipi tsa tšepe.lipeipi tšepe e sa hloekang ka aroloa ka CR letoto la lihlooho tse (400 Series), Cr Ni letoto (300 Series), Cr Mn Ni letoto la lihlooho tse (200 Series) le pula e thatafatsa letoto la lihlooho tse (600 Series).200 series - chromium nickel manganese austenitic stainless steel 300 series - chromium nickel austenitic stainless steel.

Ts'ebetso ea tlhahiso ea phala ea tšepe e se nang seamless A. ho lokisoa ha tšepe e chitja;b.Ho futhumatsa;c.Hot rolling perforation;d.Ho khaola hlooho;e.Pickling;f.Ho sila;g.Lubrication;h.Ho pitikoloha ho batang;ke.Ho fokotsa mafura;j.Tharollo kalafo mocheso;k.Ho otlolla;l.Ho khaola lipeipi;m.Pickling;n.E qetile tlhahlobo ea lihlahisoa.

Liphaephe tsa tšepe tse sa hloekang li arotsoe ka liphaephe tse tloaelehileng tsa tšepe, liphaephe tsa tšepe tsa boleng bo holimo, lipeipi tsa alloy structural, lipeipi tsa tšepe tse nang le tšepe, lipeipi tsa tšepe tse sa hloekang, liphaephe tse entsoeng ka bimetallic, liphaephe tse koahetsoeng le tse koahetsoeng ho boloka litšepe tsa bohlokoa le ho kopana le tse khethehileng. ditlhoko.

Liphaephe tsa tšepe tse sa hloekang li na le mefuta e mengata e fapaneng, litšebeliso tse fapaneng, litlhoko tse fapaneng tsa tekheniki le mekhoa e fapaneng ea tlhahiso.Hona joale, bophara bo ka ntle ba liphaephe tsa tšepe ke 0.1-4500mm 'me bophara ba lebota ke 0.01-250mm.

Pipe ea tšepe e sa hloekang e ka aroloa ka phala e se nang moeli le phala e cheselitsoeng ho latela mokhoa oa tlhahiso.Pipe ea tšepe e se nang moroko e ka aroloa ka phala e kolobisitsoeng ka ho chesa, phala e kentsoeng ka serame, e huloang ke serame le e ntšitsoeng.Ho taka ho batang le ho roala ho batang ke ts'ebetso ea bobeli ea phala ea tšepe;Welded phala e arotsoe ka otlolohile seam welded phala le spiral welded phala.Ho na le mekhoa e fapaneng ea khokahano ea liphaephe tsa tšepe tse sa hloekang.Mefuta e tloaelehileng ea lisebelisoa tsa liphaephe ke mofuta oa compression, mofuta oa compression, mofuta oa bonngoe, mofuta oa push, mofuta oa khoele ea sutu, mofuta oa socket welding, union flange connection, welding type le derivative series mode e kopanyang tjheseletsa le kgokelo ya setso.Ho ea ka morero, e ka aroloa ka phala ea seliba sa oli (casing, phala ea oli le phala ea ho phunya), phala ea liphaephe, phala ea boiler, phala ea mochini, phala ea hydraulic prop, phala ea silinda ea khase, phala ea jeoloji, phala ea lik'hemik'hale (khatello e phahameng). peipi ea manyolo, peipi ea petroleum e phunyehang) le peipi ea metsing.